The Versatility of Aluminum Bars and the Strength of Titanium Fasteners

Introduction:

Aluminum bars and titanium fasteners are two indispensable components in various industries, offering unique properties that make them highly sought after. Aluminum bars are renowned for their lightweight nature, exceptional corrosion resistance, and excellent conductivity. On the other hand, titanium fasteners boast incredible strength, durability, and exceptional resistance to extreme temperatures. In this article, we will explore the versatile applications of Aluminium bar and the strength provided by titanium fasteners.

Versatile Applications of Aluminum Bars:

Aluminum bars are widely utilized in numerous industries due to their versatility and exceptional properties. One of the key advantages of aluminum bars is their lightweight nature, making them ideal for applications where weight reduction is crucial, such as aerospace, automotive, and marine industries. They provide an excellent strength-to-weight ratio, making them a preferred choice for structural components in aircraft, lightweight frames in vehicles, and marine structures.

Additionally, aluminum bars possess remarkable corrosion resistance, enabling them to withstand harsh environments and corrosive substances. This property makes them suitable for outdoor applications, including architectural structures, window frames, and electrical enclosures.

Another notable feature of aluminum bars is their excellent thermal and electrical conductivity. This property is highly valued in industries such as electronics, heat exchangers, and power transmission, where efficient heat dissipation and electrical conduction are vital.

Aluminum bars can also be easily machined, formed, and joined, allowing for flexibility in manufacturing processes. They can be extruded, rolled, or cast into various shapes and sizes, catering to specific requirements in different industries. Furthermore, aluminum bars can be seamlessly welded, facilitating the assembly of complex structures with ease.

The Strength of Titanium Fasteners:

When it comes to fastening applications that require utmost strength and durability, titanium fasteners emerge as the top choice. Titanium possesses an exceptional strength-to-weight ratio, surpassing that of steel while weighing only half as much. This unique combination makes titanium fasteners highly desirable in industries where weight reduction is crucial without compromising structural integrity.

Furthermore, titanium fasteners exhibit excellent resistance to corrosion, especially in environments with high levels of moisture, salt, or chemicals. This property makes them invaluable in applications such as marine equipment, offshore structures, and chemical processing plants.

Titanium fasteners also excel in extreme temperature conditions, retaining their strength and integrity even at elevated temperatures. This characteristic makes them ideal for aerospace applications, gas turbines, and other high-temperature environments where reliability is paramount.

In addition to their strength and corrosion resistance, titanium fasteners are non-magnetic and exhibit excellent biocompatibility. These properties make them suitable for medical applications, including implants, surgical equipment, and prosthetics.

Conclusion:

In conclusion, aluminum bars and titanium fasteners offer remarkable properties that cater to diverse industries, providing strength, durability, and versatility in various applications.

- Share

YOU MIGHT ALSO ENJOY

Why Choose a Dumpster Rental for Junk Removal in Northwest Arkansas?

Stephen Romero - March 7, 2025

How Can Industrial Racking Improve Warehouse Organization?

Stephen Romero - March 7, 2025

Why Choose a Professional Dog Trainer in Bradenton for Your Pet?

Stephen Romero - March 7, 2025

search

must read

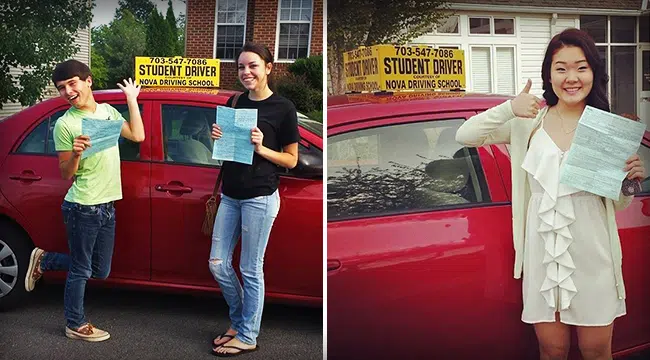

The Ultimate Guide to Finding the Best Driving School Near Me in Springfield

Stephen Romero - March 7, 2025

recent post

ARCHIVES

- March 2025 (8)

- February 2025 (9)

- January 2025 (8)

- December 2024 (25)

- November 2024 (40)

- October 2024 (11)

- September 2024 (1)

- July 2024 (10)

- June 2024 (11)

- May 2024 (31)

- April 2024 (15)

- March 2024 (19)

- February 2024 (6)

- January 2024 (7)

- December 2023 (11)

- November 2023 (1)

- July 2023 (13)

- June 2023 (21)

- May 2023 (27)

- April 2023 (23)

- March 2023 (16)

- February 2023 (31)

- January 2023 (27)

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (11)

- August 2022 (14)

- July 2022 (13)

- June 2022 (19)

- May 2022 (17)

- April 2022 (10)

- March 2022 (12)

- February 2022 (8)

- January 2022 (9)

- December 2021 (19)

- November 2021 (4)

- October 2021 (6)

- September 2021 (4)

- August 2021 (4)

- July 2021 (10)

- June 2021 (6)

- May 2021 (2)

- April 2021 (2)

- March 2021 (45)

- August 2020 (31)

- July 2020 (30)

- June 2020 (29)