stainless steel 316 tube fittings

What are solution annealed tube fittings?

Solution annealing is a heat treatment procedure that helps alter the metallurgical structure of the material. This helps change the mechanical and electrical properties of the grade. This method is primarily utilized to decrease the crack sensitivity of aged material that has to be returned to its weldable state. It affects secondary carbide precipices during high temperature service. This helps increases its ambient temperature ductility as well as its fracture toughness. Further, it also enhances its corrosion resistance properties that help change its mechanical properties. It is very important when selecting the right processing parameters for the solution annealing process. Finally, if there is no oxidation, then a vacuum process should be selected.

stainless steel 316 tube fittings

Major difference between stainless steel 316 and 316l tube fittings?

The 300 series belongs to the austenitic grade specifications. The 316 and 316l are both similar but have certain differences that set them apart in the industry. The stainless steel 316 tube fittings have a higher molybdenum content, but their carbon content is lower than the SS 316l grade. This grade has a minimum tensile strength of 515mpa with a minimum yield strength of 310mpa and can be elongated by 30%. The stainless steel 316l tube fittings, on the contrary, have a yield strength of 170mpa with a tensile strength of 485mpa. It has similar elongation. They have better welding capacity due to their lower carbon content compared to the SS316 grade. Further, the SS316L is slightly cheaper and has better resistance to intergranular than the other grade.

What are the pressure ratings of ss tube fittings?

The SS tube fittings are the maximum allowed pressure that they can withstand as the temperature increases. ASME and ANSI specification also influences the pressure rating in the industry. The grade is rated from class 150 to class 2500 or more. If you are selecting a rated tube fitting, then you should select a fastener that is rated higher than required. This will allow you to create a barrier from not collapsing under higher pressures. Its pressure rating is determined based on its design pressure and the temperature of the fitting. It is important to understand that the pound rating for the whole system is also equal to its weakest part.

What are double ferrule compression fittings?

A double ferrule compression fitting is employed to create a leakproof connection. It allows consolidation between two metric or fractional tubes. They feature a nut or two deformable ferrules in soft or non-ferrous and tube fitting that is available in metric and fractional sizes. It is available in a conventional range of sizes. They are generally available in sizes of 1/16 to 2 metric sizes. The fittings help eliminate the need for welding, making use of connecting fittings and being utilized multiple times before replacing them. Its installation is also simple with a spanner, and there are no other special equipment needs. Finally, they are globally accepted by major users across the industry.

Can 316 stainless steel tube fittings be used underwater?

Stainless steel 316 is designed with chromium, nickel, and molybdenum content. This gives them superior corrosion and oxidation resistance. They are known to work well in marine environments due to this composition. It also known to handle chlorides or halides, which are common underwater systems. Further, they also have enhanced tolerance to chloride pitting and have higher stress rupture properties. They bolster excellent tensile strength in low as well as elevated temperature setups. It can handle corrosion common in polluted marine atmospheres and has enhanced resistance to intergranular corrosive environments. They are non-magnetic in nature. All these features give them an edge in seawater services.

How to buy tested material at genuine price in UAE?

The first and most crucial step is to find and select a trusted vendor. A trustable person will offer you all the test certifications and material reports. Once you’ve checked the products, you can proceed ahead to check his inventory and stock. A supplier with a higher volume of products gives you a better opportunity to choose from products. When talking about suppliers, it is important to see which country the items are purchased from. If it is Chinese steel, then stay clear of the products as they are not of the best quality. They may be cheap, but they don’t offer the same performance and durability as other countries like India. Indian steel is amongst the best in the industry. Its quality, durability, and versatility stand out in the industry and are highly demanded all around the world.

- Share

YOU MIGHT ALSO ENJOY

A Complete Guide to Alloy Steel Pipe Manufacturers in India

Stephen Romero - November 21, 2024

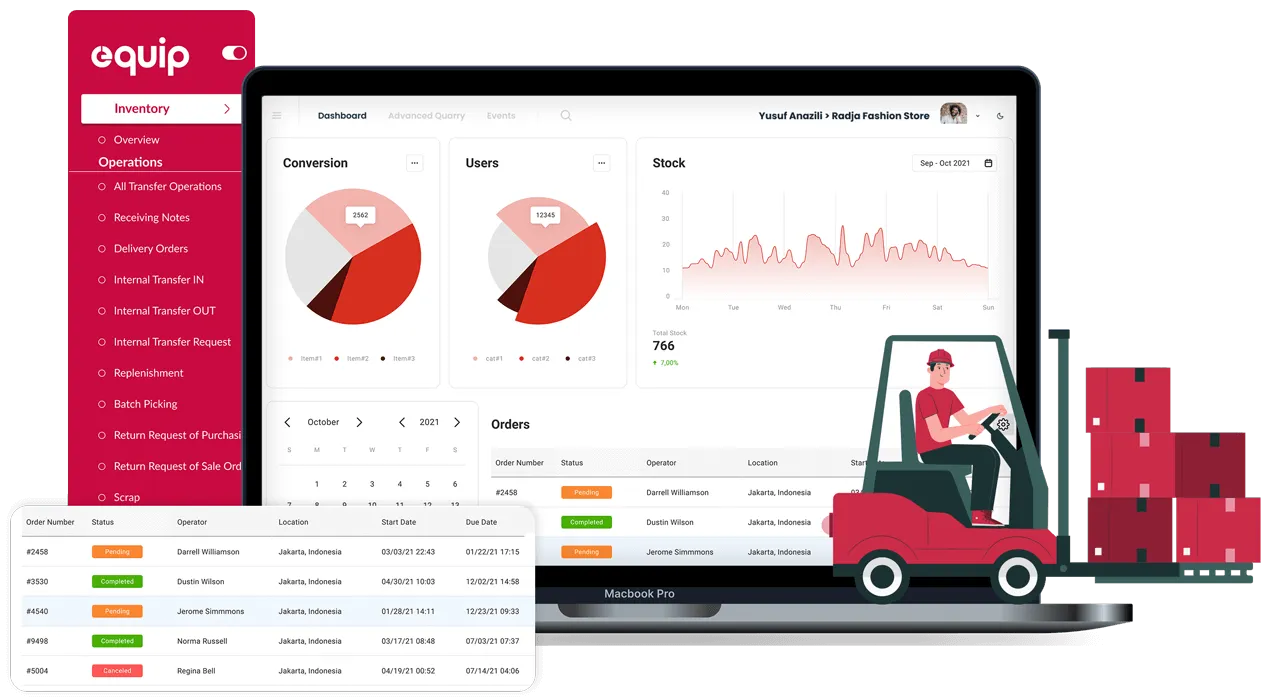

Keuntungan Apa yang Diperoleh dengan Menggunakan Aplikasi Stok Gudang dan Software Gudang dalam Bisnis Anda?

Stephen Romero - November 18, 2024

What Are the Advantages of Enrolling in Behind the Wheel Driving Schools Near Me for a Behind the Wheel Course?

Stephen Romero - November 16, 2024

search

must read

The Art of Balayage and Foil: A Guide to Perfect Hair Color in Newtown and Randwick

Stephen Romero - November 21, 2024

Stay Updated with the Latest NFL News for Today and NFL News Today Trade at FranchiseSports.co.uk

Stephen Romero - November 20, 2024

The Ultimate Guide to Choosing the Perfect Runner Rugs Australia and Large Shaggy Rug for Your Home

Stephen Romero - November 19, 2024

recent post

ARCHIVES

- November 2024 (25)

- October 2024 (11)

- September 2024 (1)

- July 2024 (10)

- June 2024 (11)

- May 2024 (31)

- April 2024 (15)

- March 2024 (19)

- February 2024 (6)

- January 2024 (7)

- December 2023 (11)

- November 2023 (1)

- July 2023 (13)

- June 2023 (21)

- May 2023 (27)

- April 2023 (23)

- March 2023 (16)

- February 2023 (31)

- January 2023 (26)

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (11)

- August 2022 (14)

- July 2022 (13)

- June 2022 (19)

- May 2022 (17)

- April 2022 (10)

- March 2022 (12)

- February 2022 (8)

- January 2022 (9)

- December 2021 (19)

- November 2021 (4)

- October 2021 (6)

- September 2021 (4)

- August 2021 (4)

- July 2021 (10)

- June 2021 (6)

- May 2021 (2)

- April 2021 (2)

- March 2021 (45)

- August 2020 (31)

- July 2020 (30)

- June 2020 (29)

.png)